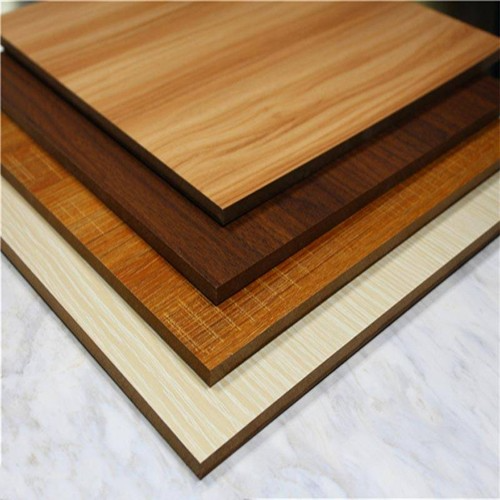

Melamine Formaldehyde (MF) and Urea Formaldehyde (UF) are high-performance thermosetting amino resins manufactured through condensation polymerization reactions. These resins are formed by reacting formaldehyde with melamine or urea respectively, creating cross-linked polymer networks that deliver exceptional hardness, high gloss finish, superior heat resistance, and outstanding adhesive strength.

Our manufacturing technology produces both resin types with precise control over molecular weight, cross-linking density, and performance characteristics, making them ideal for demanding applications in wood processing, decorative laminates, and molded products.