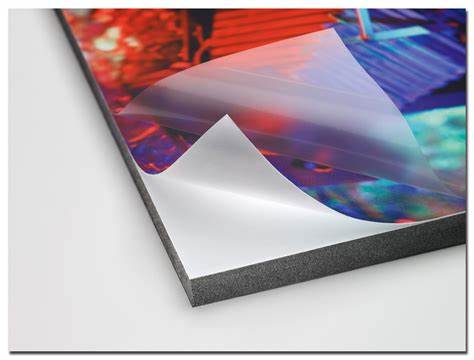

Wet lamination adhesives are specialized bonding solutions used in film-to-substrate laminating applications, where the adhesive is applied in a liquid (wet) state to one substrate, and lamination with the second substrate occurs before the adhesive is dried or cured. The system relies on pressure and subsequent drying or curing to develop strong adhesion between the layers.

Key Application Industries

Wet lamination is commonly employed in the packaging industry, where materials such as polyester (PET), BOPP, aluminum foil, and paper are laminated to another porous substrate to achieve desirable barrier, mechanical, or aesthetic properties.